In May 2019, Michael and Jodie Flowers, owners of Commercial Laundry Solutions, travelled to Cambodia to install four reconditioned Electrolux commercial washing machines and a drier that they had donated, at the Khmer Soviet Friendship Hospital. This hospital is the biggest and poorest public hospital in the country and sees over 1000 patients a day. Electrolux had provided $6,000 of parts to update and refurbish the washing machines alongside Challenge Chemicals who agreed to donate 1000 litres of detergent, which was shipped earlier in the year. The Flower's were accompanied and assisted by volunteer nurse educator, Kareen Dunlop, who filed this report.

Over the years whilst volunteering in Cambodia at the Khmer Soviet Friendship Hospital (KSFH) in Phnom Penh, staff have been pleading with me in regards to their laundering. To date, education, hand hygiene and cleaning have taken priority.

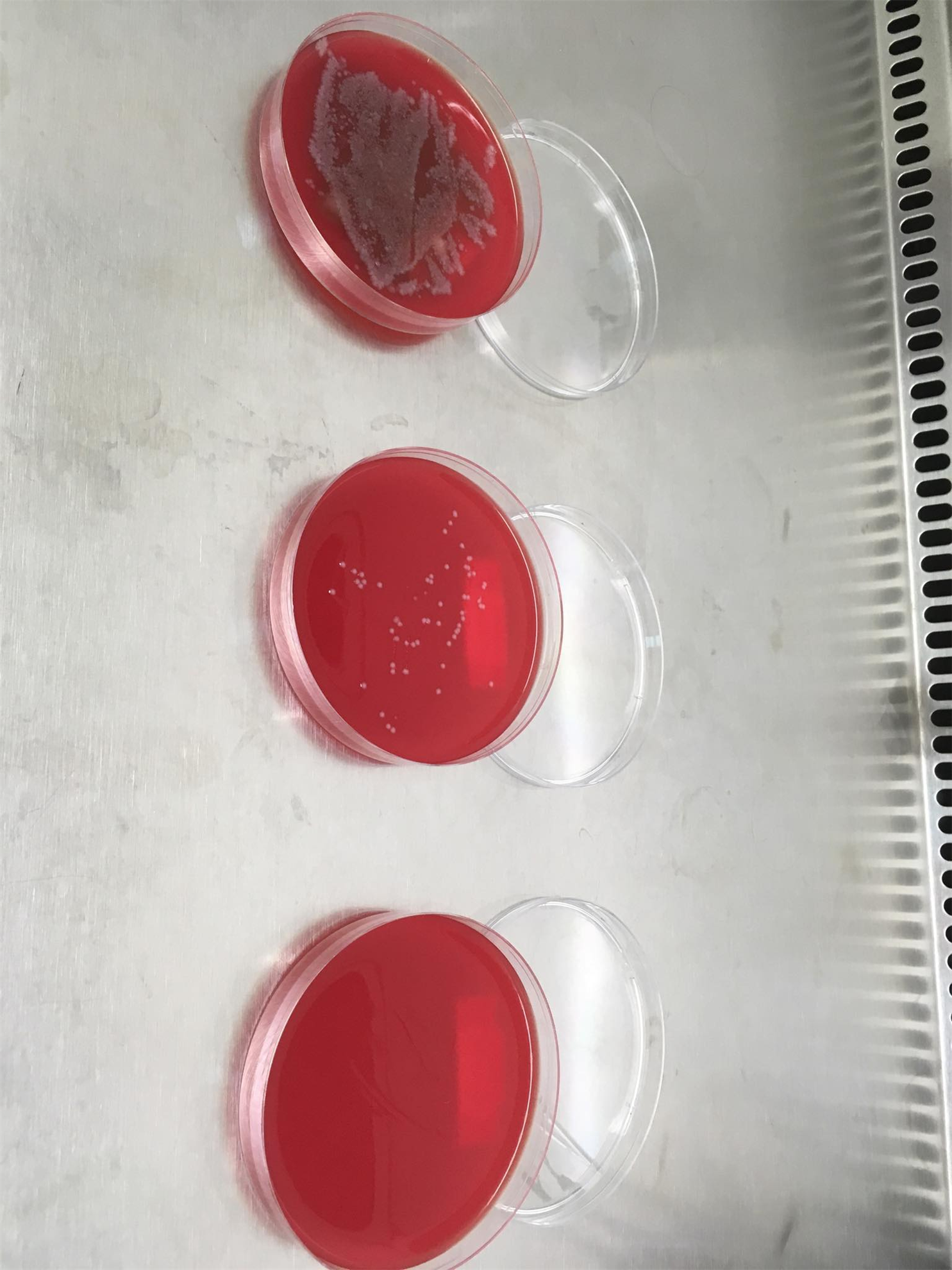

In one of my mentoring sessions in early 2018, the Deputy Infection Control Coordinator, Nhib Chhom again said how the washing was coming back from the laundry dirtier than it went. I requested that she test the washing machines ability to reduce bacteria using agar plates, by pressing it onto the laundry prior to washing and immediately after washing. The results showed a very minor reduction in the number of bacteria on the washing. Nita Mean, the Infection Control Coordinator sought two quotes for a large industrial washing machine, however these were just simply beyond my fundraising capabilities.

From this time, I kept my ear out for a hospital removing their washing machine. Having found two at Bethesda Hospital I called their service provider, Michael Flowers from Commercial Laundry Solutions to ask for a quote to service them, prior to removal. He suggested I come and talk to him as he may have a better solution. There I met Michael’s wife and business partner, Jodie who had been wanting to do something charitable but didn’t know what. Well what an opportunity for KSFH! Michael and Jodie had four used Electrolux industrial washing machines, and offered to refit them for this project.

From this time, I kept my ear out for a hospital removing their washing machine. Having found two at Bethesda Hospital I called their service provider, Michael Flowers from Commercial Laundry Solutions to ask for a quote to service them, prior to removal. He suggested I come and talk to him as he may have a better solution. There I met Michael’s wife and business partner, Jodie who had been wanting to do something charitable but didn’t know what. Well what an opportunity for KSFH! Michael and Jodie had four used Electrolux industrial washing machines, and offered to refit them for this project. They both took this project on with gusto and were able to get the support of Electrolux Australia Country Manager, Shaun Petrie to supply the parts they required to refit the washing machines. This required fitting in reworking the machines around their normal busy schedule, to get them ready in time to go in a container that was being packed by Osborne Park Rotary Club (OPRC). They also spoke to Martin Cattalini from Challenge Chemicals who agreed to donate 1000L of detergent.

Timing was important to allow for shipping of the machines, detergent, booking of airfares and to work around our schedules. Thankfully financial support was offered by a personal friend to cover accommodation, flights, installation costs and any incidentals we might require during our trip to install the machines, which enabled us to book our flights early. As this was Michael and Jodie’s first trip to Cambodia, I accompanied them to introduce them to the hospital executive, orientate them to the hospital and Phnom Penh and ensure the process went smoothly.

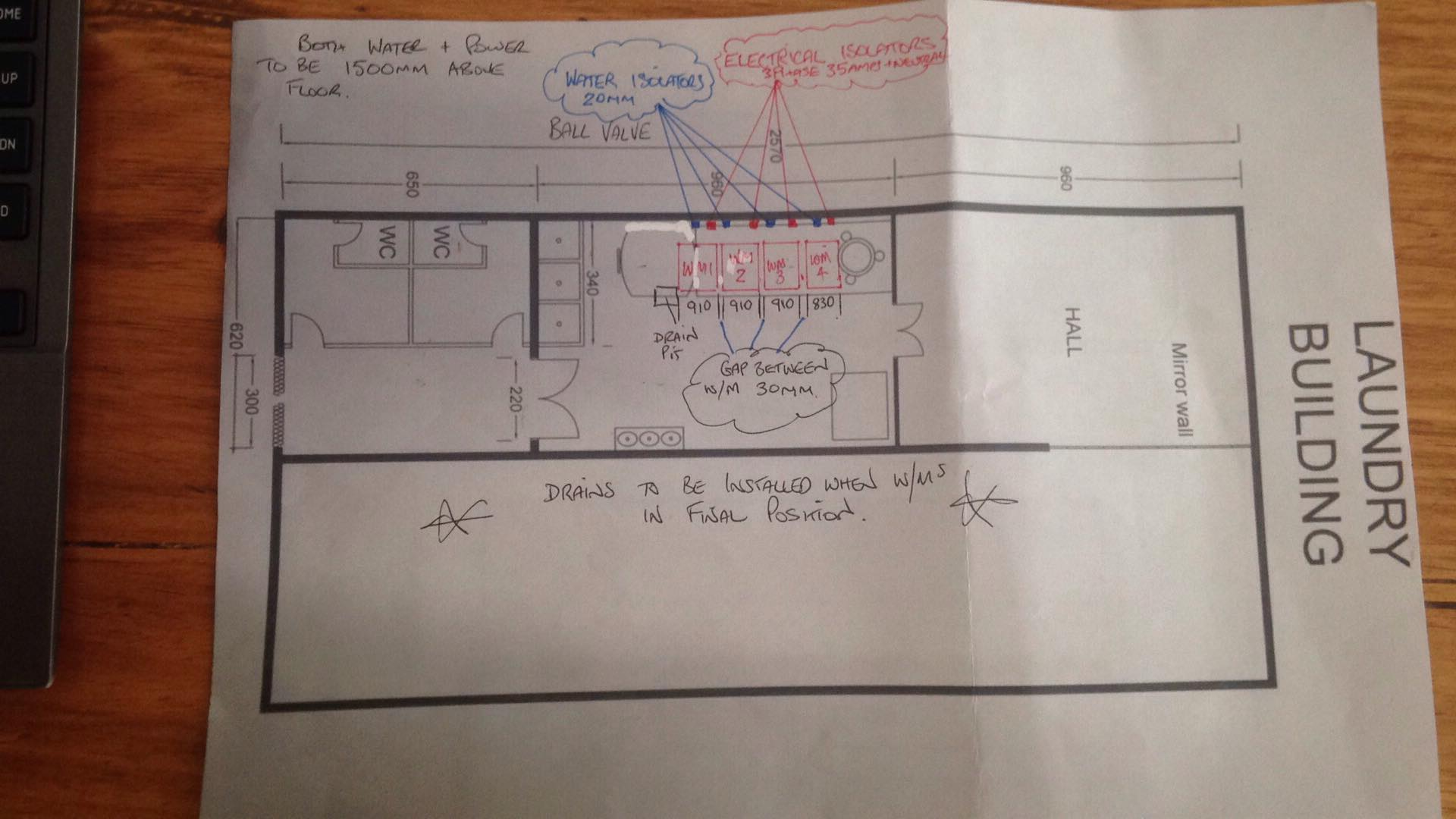

Whilst the machines were being refitted, the laundry plan was looked at by Michael to work out where the machines could go, then power points and water piping added to the map. The hospital was asked to install 3 phase electrical points for each machine, 20mm water pipes with a ball valve. An online group was formed on messenger with Raksmey, the chief of maintenance at the hospital, so we could all communicate easily. Michael needed to check what tools were available at the hospital and we needed to plan how and when we would remove the current washing machine. Pictures flew back and forth to ensure the work was done prior to arranging shipping of the machines. Thankfully this was all done by our arrival. Michael also offered to convert a gas dryer to electrical so it could be sent up with the washing machines.

Pip Asphar from OPRC arranged with the Flowers to pick up the machines and detergent which was then transferred to the shipping yard. One Saturday early March a group of Rotarians, my husband and I packed a shipping container with medical equipment including the machines and detergent. The container was sent to Sihanoukville, the port of Cambodia, where the hospital organised for it to be transferred to them. There was a momentary panic when one of the photo’s showed that the machines had been opened and we wondered whether tools had been removed from them somewhere along the journey. However the hospital electrician Raksmey, had opened it to check the pipe diameter and we were able to breathe again.

May 17, saw Michael, Jodie and myself on a plane bound for Cambodia, via Singapore with bags full of tools. We arrived at 0840 the following the morning and after a very quick hotel check in it was off to the hospital with Yut, my regular tuk-tuk driver. We had a quick meeting with deputy director, Dr Lim Taing, Nhib and Raksmey, a walk to the laundry followed by lunch with the Nurse Leadership Team. Raksmey had organised his whole maintenance team of five men to assist Michael with the installation, which was most helpful. They worked through the three public holidays and the weekend whilst we were there, as did Nhib of which they would not have received any extra remuneration for. I used part of the generous donation to pay them an extra US$40 each, as their wages are US $200/month and you need US$450 just to live under a bridge there.

May 17, saw Michael, Jodie and myself on a plane bound for Cambodia, via Singapore with bags full of tools. We arrived at 0840 the following the morning and after a very quick hotel check in it was off to the hospital with Yut, my regular tuk-tuk driver. We had a quick meeting with deputy director, Dr Lim Taing, Nhib and Raksmey, a walk to the laundry followed by lunch with the Nurse Leadership Team. Raksmey had organised his whole maintenance team of five men to assist Michael with the installation, which was most helpful. They worked through the three public holidays and the weekend whilst we were there, as did Nhib of which they would not have received any extra remuneration for. I used part of the generous donation to pay them an extra US$40 each, as their wages are US $200/month and you need US$450 just to live under a bridge there. The hospitals current washing machine was going when we arrived and was “spewing” out soap suds all over the floor which the laundry worker was hosing away. With daily temperatures of 35-38oC and humidity well over 80% one of our first purchases was a pedestal fan to keep Michael slightly comfortable, a cloth to wipe away sweat and an extension lead. All credos to Michael for working in that heat with no air-conditioning. By the end of the first afternoon the concrete floor was dried off and the bolts fixed in for three of the machines. The following day saw one machine in and up and working, the old spinner removed and the other three machines lifted into the laundry. Michael showed the laundry staff how to use the first machine so that the old machine could be disabled and eventually removed. The guys lifted most of these machines into place – pure manpower. Water filters were placed on the incoming water and drainage holes covered in and retiled. By Wednesday the old machine was gone, all machines in and working and the dryer installed and awaiting an exhaust outlet.

On Tuesday, I gave a lecture to all the charge nurses and the two laundry staff on how to manage their laundry services including the importance of hand hygiene, protective wear and segregation to prevent cross contamination. This latter point was quite a task to implement as the laundry staff had not been trained in the concept of “bugs” nor segregation. Prior to arriving laundry was predominantly tied up in a used sheet, transferred to the laundry on an old patient trolley, then put without sorting into the one washing machine. This allowed colours to run between them. To assist keeping flat sheets on the bed, some wards tie knots in each corner of the sheets to assimilate a fitted sheet, however these were never undone when put through the laundry meaning they are not cleaned thoroughly. As the washing was not sorted, various articles from the wards, such as scalpel blades, urine bags and tape are often left in the load. This is not only dangerous to those handling the linen, but in the case of tape cooks it onto the linen and damages the machines.

Five wheeled bins were donated by Michael and Jodie, two of which we asked the laundry staff to use to sort the washing, and three spring loaded to cart clean washing to the dryer and out of the dryer. Waterproof aprons and gloves were supplied from Perth and hooks drilled into the wall to hang them. Washed laundry used to be put in a large red “rubbish” bin and dragged across to the dryer. From the dryer it was put on the floor in the packing room, where in the evening it was folded on the floor and put in linen carts (previously supplied from Perth hospitals). Four stainless steel tables were bought and installed in this room so they had somewhere to fold the dry linen.

On the Wednesday Nhib and I checked a post wash load with agar plates. A small amount of a waterborne (or soil) bacteria, Acinetobacter were found. We then increased the temperature of the wash to 75oC and retested the same load pre, post and after drying the next day. This showed a substantial decrease in the bioburden of the laundry post washing and complete annihilation of all bacteria post drying. So, a wonderful success which was reported to the Director.

I also spent time working with the Nurse Leadership Team going through issues they had. The staff educator wanted to know how to put together an orientation for all hospital staff, so we devised the framework for a general hospital orientation followed by individual ward orientation. I also discussed with him how to use power point for presentations. Nhib and I discussed measures on how to encourage the doctors working clinically to be bare below the elbow so that they can wash their hands effectively. We have designed a poster and the Director has agreed to show himself with his sleeves rolled up to be an example to all staff. As the Director has utmost power in the hospital this will be the most effective way to encourage staff to roll their sleeves up. I also worked with Nhib to show her how to influence behavior by sandwiching poor behavior between praise. She was most surprised to the attitude of staff when I demonstrated this.

On our last few days there the tropical rains arrived. Jodie and I were left in the dark in a store one day, whilst a great thunderstorm raged overhead. Once the rain fell vertically, we ran out to Yut who had enclosed the tuk tuk. He safely delivered us back through the flooded grounds of the hospital to the laundry, so we could deliver a carton of beer and the monetary gifts to the maintenance team to thank them for working the public holidays and weekends. Unfortunately, the back of the hospital is often flooded by groundwater streaming in from the slums across the road. Patients and staff are forced to walk through it to get from one department to another.

It may take a while for the laundry staff to learn to sort washing and learn how to keep dirty separate from clean, however after spending time with them and Nhib promising to go there every day for the next 3-4 weeks, I believe the staff will have learnt to manage a much improved process. The final thing we were waiting on was an exhaust fan to remove the lint from the dryer, which arrived the day we left. In conclusion the project was a wonderful success. Jodie and Michael have offered to go back at least annually to service the machines until the maintenance staff are able to do this themselves. I would like to personally and on behalf of the hospital Directors and staff thank all those who were responsible as a team to assist this project run so smoothly. Your time, donations and kindness will benefit so many.

.jpg)

Khmer Soviet Friendship Laundry Project Report

May 2019

With Grateful thanks to the following people without whom this project would not have been possible.

Michael and Jodie Flowers

Anonymous donor

Electrolux Australia

Osborne Park Rotary Club

Challenge Chemicals

Thank you